Introduction

Heating, Ventilation, and Air Conditioning (HVAC) systems are fundamental to the comfort, safety, and functionality of modern buildings. For Mechanical, Electrical, and Plumbing (MEP) professionals, especially those starting their careers, having quick reference thumb rules and formulas is invaluable for preliminary design, sanity checks, and faster decision-making.

This Level 1 guide provides a collection of essential rules and formulas.

These HVAC MEP thumb rules are widely applied across projects in the USA, Germany, UAE, India, and other global engineering markets

Disclaimer: These are for initial estimation and conceptual design only. Detailed and final engineering must always be based on comprehensive calculations, local codes, and standards like ASHRAE.

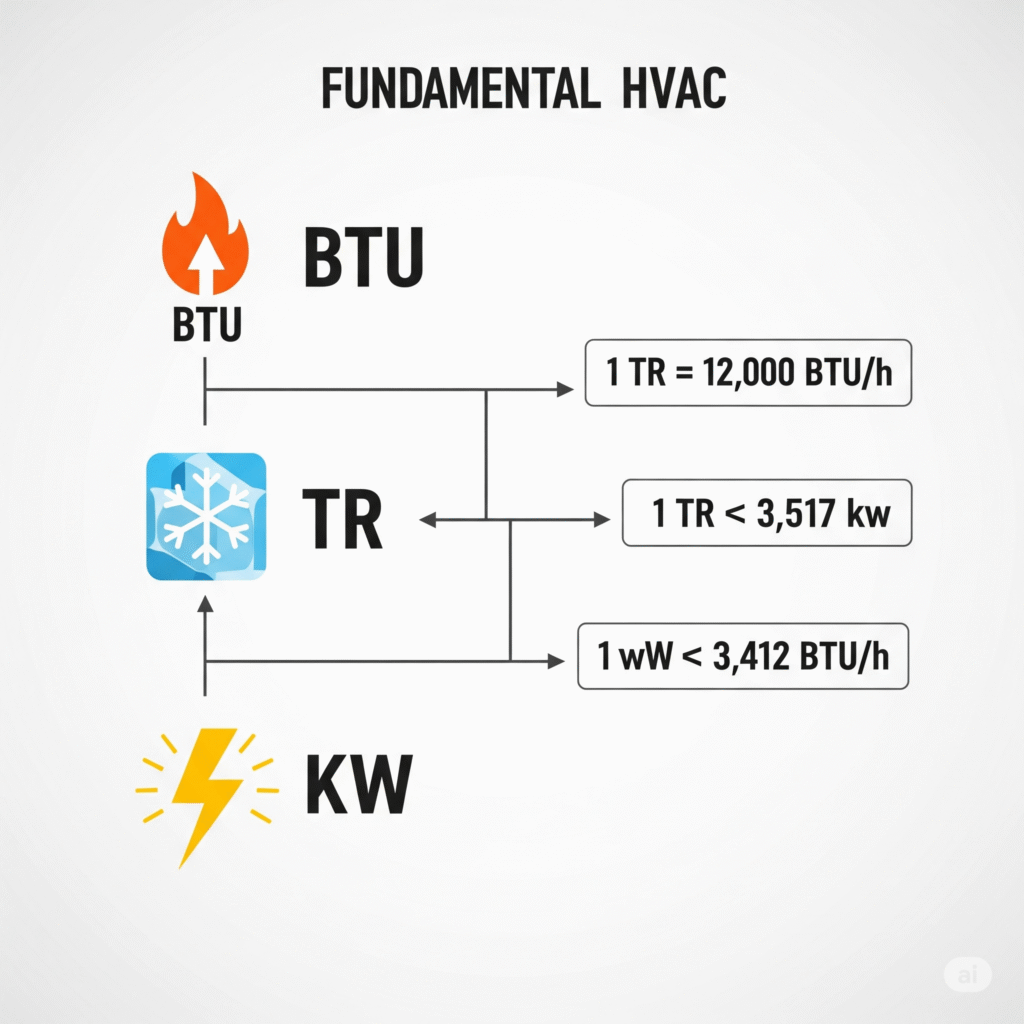

1. Fundamental Concepts & Conversions

- BTU (British Thermal Unit): The amount of heat required to raise the temperature of one pound of water by one degree Fahrenheit.

- Ton of Refrigeration (TR): A measure of cooling capacity.

- 1 TR=12,000 BTU/hr

- 1 TR=3.517 kW

2. Cooling Load Estimation

This is the first step in sizing any HVAC system. It estimates the total amount of heat that needs to be removed from a space.

Formula (Area-Based Method):

Q(BTU/hr)=Area (sq ft)×Heat Load Factor (BTU/hr per sq ft)

Thumb Rules for Heat Load Factor:

- Residential: 20–30 BTU/hr per sq ft

- Office (Standard): 30–40 BTU/hr per sq ft

- Retail/Commercial: 35–55 BTU/hr per sq ft

- Restaurant/Kitchen: 60–100+ BTU/hr per sq ft

Example: For a 2,000 sq ft office space:

Q=2,000 sq ft×35 BTU/hr per sq ft=70,000 BTU/hr

3. Airflow (CFM) Calculation

Airflow, measured in Cubic Feet per Minute (CFM), is crucial for distributing conditioned air.

A. Total Airflow based on Cooling Load: This is the most common thumb rule for total supply air.

- Rule: 1 TR of cooling requires approximately 400 CFM of airflow.

- Formula: Total CFM=Total TR×400

Example: An office requires a 5 TR AC unit (60,000 BTU/hr÷12,000).

Required Airflow=5 TR×400 CFM/TR=2,000 CFM

B. Ventilation (Fresh Air) Airflow: This is the outdoor air required for occupant health and comfort (as per ASHRAE 62.1).

- Rule (per person):

- Office: 15–20 CFM per person

- Cleanroom: 10–15 CFM per person

- Residential: 7.5 CFM per person + 3 CFM per 100 sq ft

Example: For an office space with 30 occupants:

Required Fresh Air CFM=30 persons×20 CFM/person=600 CFM

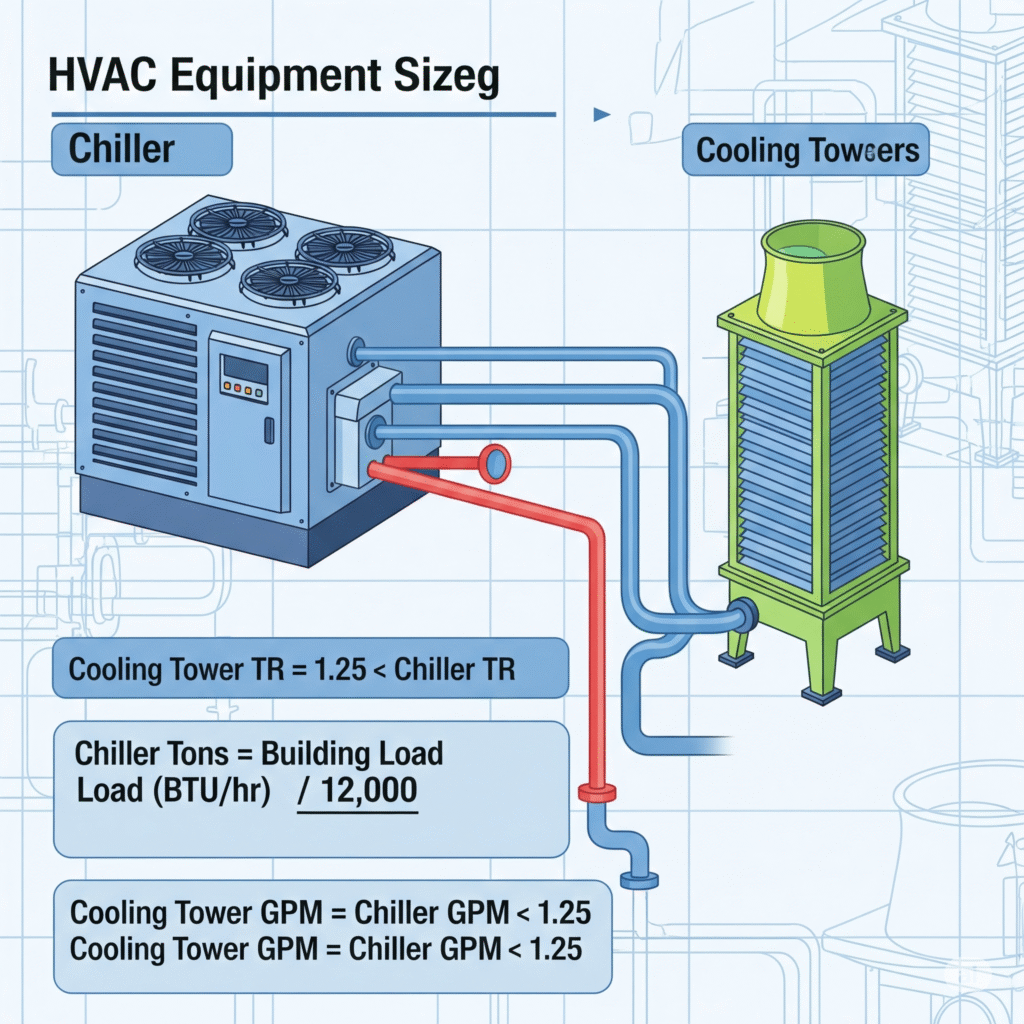

4. Equipment Sizing

A. Chiller / AC Unit Sizing:

- Formula: Tonnage (TR)=12,000Total Heat Load (BTU/hr)

Example: For a total heat load of 70,000 BTU/hr:

TR=12,00070,000 BTU/hr≈5.83 TR

(You would select the next standard available size, likely a 6 TR unit.)

B. Cooling Tower Sizing: A cooling tower rejects heat from the chiller’s condenser plus the heat of compression from the compressor.

- Thumb Rule: Size the cooling tower for 1.25 to 1.5 times the chiller’s cooling capacity.

- Formula: Cooling Tower TR=Chiller TR×1.25

Example: For a 100 TR chiller:

Cooling Tower Capacity=100 TR×1.25=125 TR

5. Water Systems (Chilled Water)

A. Chilled Water Flow Rate:

- Formula: GPM=500×ΔTBTU/hr

- Where GPM is Gallons Per Minute.

- ΔT is the temperature difference between supply and return water (typically 8–12∘F).

- The constant ‘500’ is derived from (8.33 lbs/gal×60 min/hr).

Example: For a 5 TR load (60,000 BTU/hr) and a ΔT of 10∘F:

GPM=500×1060,000=12 GPM

- Quick Rule: 1 TR requires approximately 2.4 GPM for a 10∘FΔT.

B. Pipe Sizing (GPM Based): Pipe size is selected to keep water velocity within an acceptable range to minimize noise and erosion.

- Thumb Rule: Target a water velocity of 2 to 4 feet per second (ft/s).

- Reference Table (Schedule 40 Steel Pipe):

| Pipe Size (inch) | Approx. GPM Range (at 2-4 ft/s) |

| 1″ | 5 – 10 GPM |

| 1.5″ | 15 – 30 GPM |

| 2″ | 25 – 50 GPM |

| 2.5″ | 40 – 80 GPM |

| 3″ | 60 – 120 GPM |

| 4″ | 120 – 240 GPM |

Export to Sheets

Example: For a required flow of 35 GPM, a 2-inch pipe is a suitable choice.

C. Pump Head & Power Calculation: Pump “head” is the pressure required to overcome friction losses and elevation changes.

- Head Estimation Rule: A very rough estimate is 4-6 ft of head for every 100 equivalent feet of pipe run. Detailed calculation is required for accuracy.

- Pump Power Formula (Brake Horsepower): BHP=3960×ηGPM×Head (ft)

- Where η (eta) is the pump efficiency (typically 0.65 to 0.85).

Example: A pump needs to deliver 120 GPM against a total head of 80 ft, with an efficiency of 75% (0.75).

BHP=3960×0.75120×80≈3.23 HP

(You would select the next standard motor size, likely 5 HP.)

6. Air Distribution (Duct Sizing)

Proper duct sizing ensures air reaches all spaces quietly and efficiently.

- Main Duct Velocity: 1000–1500 FPM (Feet per Minute)

- Branch Duct Velocity: 600–900 FPM

- Area Calculation: Duct Area (sq ft)=Velocity (FPM)CFM

- Rule of Thumb (Low Pressure): For quick sizing of rectangular ducts, allow 1 square inch of duct area for every 10-15 CFM of airflow.

Example: For a branch duct carrying 300 CFM:

Required Area≈10 CFM/sq.in300 CFM=30 sq in

(This could be a 6″x5″ or 8″x4″ duct.)

Conclusion

These basic HVAC thumb rules and formulas provide a reliable starting point for new MEP professionals. They help in quickly estimating load requirements, sizing primary equipment, and guiding initial system design with more confidence. For detailed and energy-efficient designs, always proceed to Level 2: Advanced Calculations and System Optimization using industry-standard software and codes.

Stay tuned!

This blog post is an excellent Level 1 reference guide for HVAC and MEP professionals.

it would be good If you add some practical examples and Numbers for more clear understanding.

Highly recommend sharing this resource within engineering teams, HVAC contractor groups, and technical community.

Thank you Alex for the feedback. I really Appreciate it. More details will be covered in Level 2.