Background

A pharmaceutical facility operating a 450 TR cooling tower faced rising energy bills and declining cooling performance. Despite proper maintenance of fans and pumps, condenser water temperature consistently stayed 1.5–2°C higher than design values. This meant the chillers were working harder, driving up electricity consumption and reducing overall system reliability.

Problem Identified

A detailed inspection revealed:

- Degraded Fills: PVC fills had become brittle and partially clogged with scale and bio-growth. This reduced the surface area available for effective air–water contact.

- Faulty Nozzles: Several spray nozzles were eroded or clogged, creating uneven water distribution and dry spots in the fill.

- Impact: Reduced heat transfer efficiency, higher approach temperatures, and greater load on chillers.

Solution Implemented

The facility carried out a targeted fill and nozzle upgrade:

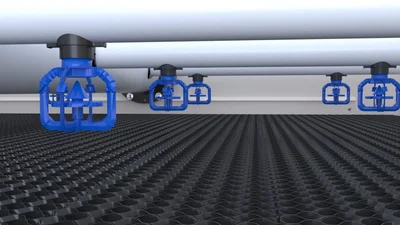

- Replaced old splash fills with high-efficiency film fills, improving surface contact and thermal performance.

- Installed low-pressure, non-clogging nozzles to ensure uniform water distribution.

- Performed chemical cleaning and descaling during the retrofit.

- Enhanced water treatment and added side-stream filtration to protect the new media.

Results Achieved

The comprehensive fill and nozzle upgrade yielded significant and measurable improvements:

- Approach Temperature Improvement: Leaving condenser water temperature reduced by an average of 1.8°C, indicating much more efficient heat rejection.

- Chiller Energy Savings: Each degree Celsius improvement reduced chiller power by ~3%. For the 450 TR system, this meant 15–20 kW savings per chiller.

- Cooling Tower Fan Savings: Better heat transfer allowed fans to run at lower speeds, delivering 8–10% savings in fan power.

- Overall Benefits:

- Total plant energy reduction: ~7–9%

- Annual savings: ₹8–10 lakhs (based on 16–18 hrs/day operation)

- Payback period: < 1.5 years

Key Learnings

- Fills and Nozzles Are the “Heart” of a Cooling Tower: Even with efficient fans and pumps, poor water distribution or degraded fills choke performance.

- Small Temperature Changes = Big Energy Losses: Just a 1–2°C increase in leaving water temperature can amplify chiller energy consumption significantly.

- Hidden Inefficiencies: Routine O&M often misses fill/nozzle degradation. A structured inspection program is essential.

- Beyond Energy Savings: Restored cooling capacity ensures stable operations during peak ambient conditions.

Takeaway

While advanced solutions like VFDs and smart controls are effective, sometimes the simplest retrofit delivers the highest return. Upgrading cooling tower fills and nozzles is a low-cost, high-impact strategy, with immediate payback in both energy efficiency and system reliability.

For any facility with cooling towers older than 7–10 years, a fill and nozzle inspection should be a priority. The savings could be hiding in plain sight.

Very Nice Sir ji

Very nice sir 👍