Well, folks, after more than three decades in this industry, you learn a thing or two about where the real energy guzzlers hide. And if you’re in pharmaceuticals, let me tell you, there’s a massive beast lurking in your utility closet that often gets overlooked until the power bill arrives: your chiller system.

Now, I’ve seen countless facilities, from gleaming new builds to venerable old plants, and the story is almost always the same. We spend fortunes on cleanrooms, sophisticated processing equipment, and state-of-the-art automation. All vital, no doubt. But the humble chiller, the unsung hero keeping everything cool, often gets treated like an afterthought. And that, my friends, is a mistake that costs millions.

The Pharmaceutical Predicament: Why Chillers are King (and Cost)

Think about it. Pharmaceuticals aren’t just about making pills; they’re about precision. Temperature control is paramount. Whether it’s maintaining the integrity of sensitive APIs, ensuring optimal conditions for fermentation, or keeping analytical instruments within their narrow operating ranges, consistent cooling is non-negotiable.

This isn’t a factory making widgets where a few degrees here or there won’t matter. In pharma, a temperature excursion can mean ruined batches, regulatory headaches, and ultimately, a significant hit to your bottom line. So, we run our chillers hard, often 24/7, year-round. And therein lies the “cold truth” about your energy bills.

In a typical pharmaceutical plant, chillers can account for a staggering 30–40% of total energy consumption. Let that sink in for a moment. That’s a massive slice of your operational budget going towards cooling.

The Hidden Costs: Beyond the Initial Investment

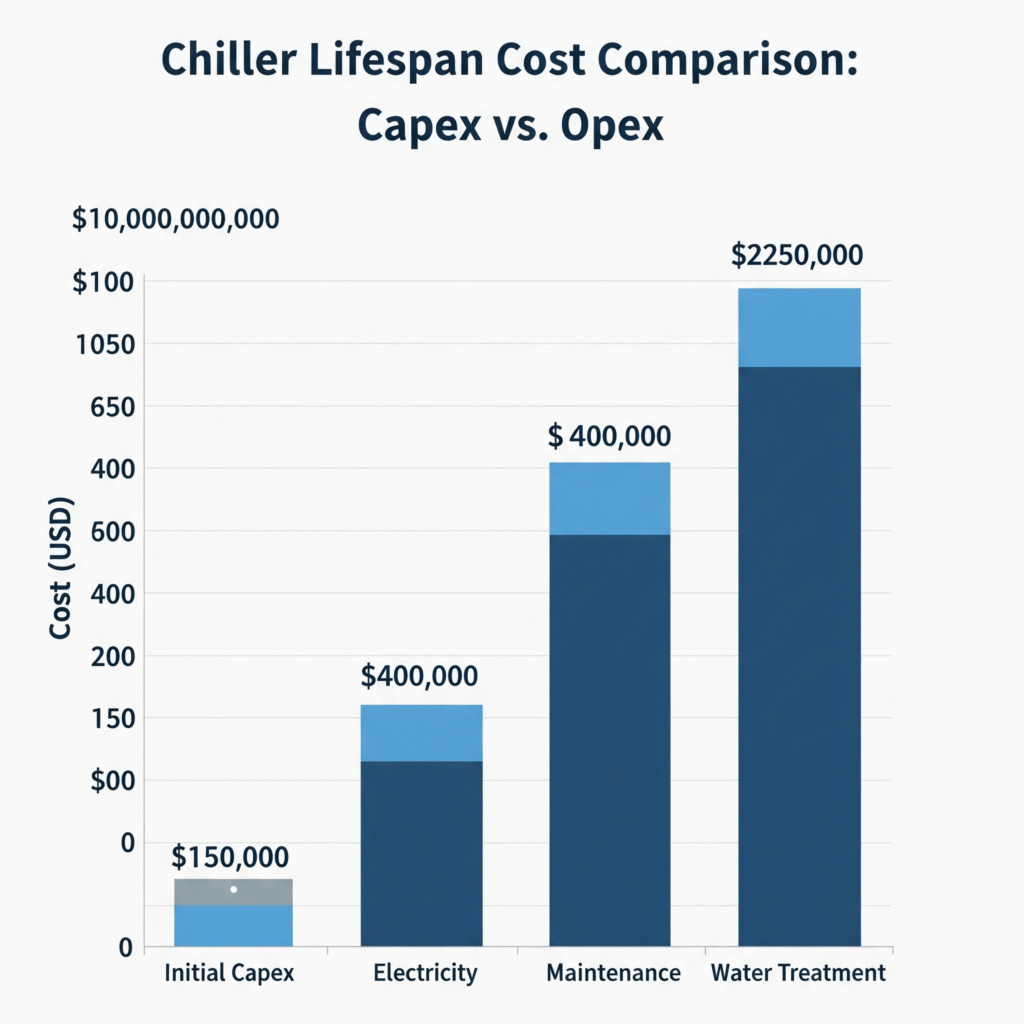

Sure, buying a chiller is a big capital expenditure. But that’s just the tip of the iceberg.

The real ongoing cost lies in its operation. We’re talking about electricity consumption that can dwarf other equipment in your plant.

I remember one project where we were auditing an older facility. Their chillers were ancient, oversized, and running far less efficiently than modern units. When we did the numbers, the energy savings from upgrading just one of their main process chillers would have paid for the new unit in less than three years. Three years! That’s a return on investment you don’t often see in this business.

Where to Look for Savings: My Top 3 Areas for Pharmaceutical Chiller Efficiency

So, if you’re looking to chip away at those formidable energy bills, here’s where my experience tells me you should focus your attention for reducing pharma energy bills:

- Right-Sizing and Redundancy: Many plants have oversized chillers, a legacy of “just in case” thinking or expansion plans that never fully materialized. An oversized chiller cycles more, leading to inefficiencies. On the flip side, inadequate redundancy can lead to operational nightmares if a unit goes down. It’s a delicate balance, and getting it right through proper load analysis is crucial. Don’t just replace like-for-like; understand your actual cooling demand.

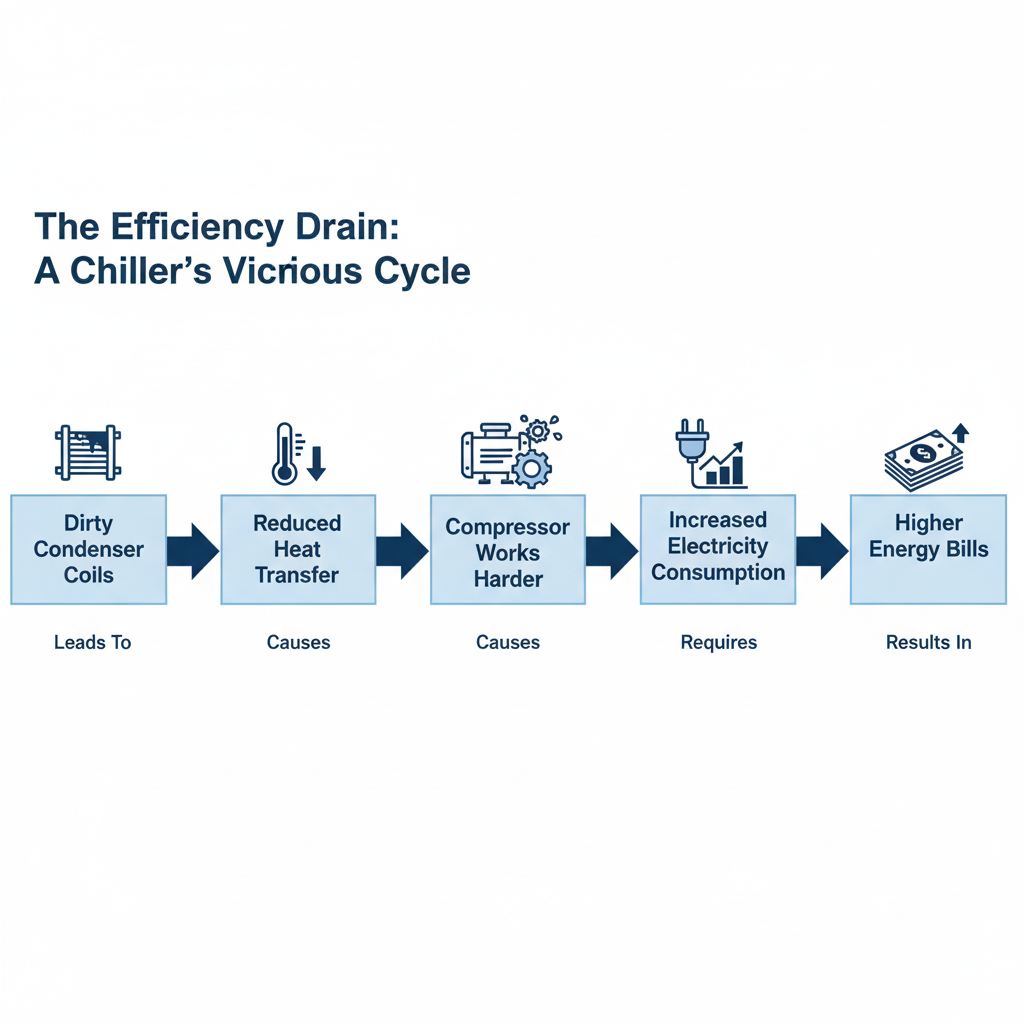

- Maintenance, Maintenance, Maintenance: This cannot be stressed enough. A properly maintained chiller is an efficient chiller. This includes:

- Condenser Coil Cleaning: Dirty coils are insulators. They force the compressor to work harder, consuming more electricity. Regular cleaning is a low-cost, high-impact activity.

- Refrigerant Charge: Too much or too little refrigerant throws the whole system out of whack. Regular checks by certified technicians are non-negotiable.

- Water Treatment: If you’re running a water-cooled chiller, scale and biological growth in your cooling towers and heat exchangers will kill efficiency faster than you can say “BTU.” Proper water treatment is critical.

- Preventive Maintenance Schedules: Don’t wait for a breakdown. Implement robust PM schedules based on manufacturer recommendations and operational data.

- Embrace Modern Technology (Where it Makes Sense):

- Variable Frequency Drives (VFDs): If your cooling load fluctuates (and in most pharma plants, it does), VFDs on compressors and pumps can be game-changers for HVAC optimization in cleanrooms. They allow the motor to operate at the exact speed required, rather than running full tilt all the time.

- Newer Refrigerants: Older chillers might be using refrigerants that are less efficient or being phased out. While a full conversion can be costly, understanding the long-term implications and benefits of newer, more environmentally friendly options is smart planning.

- Absorption Chillers / Cogeneration: For facilities with significant waste heat or access to cheap natural gas, absorption chillers can turn “waste” into valuable cooling, drastically reducing electricity demand. It’s not for everyone, but definitely worth exploring.

- Smart Controls & Optimization: Modern chiller plants have sophisticated control systems that can optimize operation, manage multiple units for peak efficiency, and even integrate with building management systems. Investing in these can provide significant returns.

Don’t Let it Become a “Set and Forget” System

The biggest mistake I see, time and again, is treating the chiller system as a “set and forget” utility. It’s not. It’s a dynamic, complex piece of equipment that requires ongoing attention, optimization, and strategic investment. Your facility’s cooling needs will evolve. Production scales up, new processes are introduced, and even ambient conditions shift over the years. Your chiller strategy needs to adapt alongside these changes.

If you haven’t audited your chiller plant in the last 3 years, you’re leaving money on the table. The cold truth? Your next big energy saving won’t come from new equipment on the production floor — it’ll come from your cooling plant.

Nice one Varun sir..