In every industrial facility, energy losses are like invisible leaks—they drain money, reduce equipment life, and increase electricity bills without anyone noticing.

- Boilers lose heat to the atmosphere.

- Chillers struggle with unwanted heat gain.

- Brine plants waste valuable cooling capacity.

The result? Higher energy consumption, overloaded systems, and lakhs of rupees lost each year.

Let’s break this down—by calculating losses, then by showing how insulation pays for itself in record time.

So, we will Start with What is Insulation and types of insulation.

What is insulation

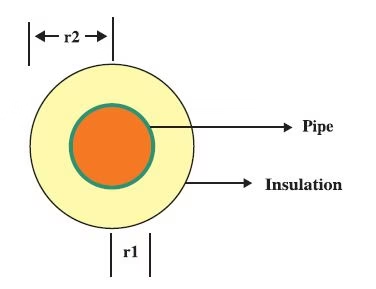

Insulation is a protective layer of material applied to equipment, pipes, or tanks to reduce unwanted heat loss or gain, maintain process temperatures.

In simpler terms: it keeps hot things hot and cold things cold, while also preventing burns, condensation, or frost on surfaces.

For industrial systems:

- Pipes & Water Systems → Maintain temperature, avoid freezing or heating.

- Boilers → Reduce heat loss from steam and hot water.

- Chillers & Brine Plants → Minimize cooling loss and condensation.

Types of Insulation in Industrial Systems

| Type of Insulation | Material | Typical Temperature Range | Applications |

| Thermal / Hot Insulation | Mineral wool / Rock wool / Glass wool | Up to 650°C | Boiler walls, steam & hot water pipes, hot tanks |

| Calcium silicate / Ceramic fiber | 650°C to 1200°C | Extremely high-temp areas like boiler walls, steam lines | |

| Low-Temperature / Cold Insulation | Foam insulation (PU, PIR, PE) | -50°C to 100°C | Chilled water pipes, low-temperature applications |

| Elastomeric foam (NBR/PVC) | -50°C to 120°C | Chilled water piping, brine pipelines, cold storage tanks | |

| Polyethylene foam | -40°C to 80°C | Chilled water piping, brine pipelines, cold storage tanks | |

| PIR / PU foams | -50°C to 100°C | Chilled water piping, brine pipelines, cold storage tanks |

Why Focus on Losses?

Most companies talk about savings, but savings only matter when you know what you’re losing right now.

👉 By calculating actual heat loss (without insulation) and comparing it with insulated pipes, the numbers become crystal clear.

The approach is simple:

- Calculate baseline energy losses without insulation.

- Apply the correct insulation properties and recalculate.

- Compare the two results → this difference is your real saving.

⚡ Enjoying this article? Stay updated with weekly HVAC & Energy Hacks — straight on WhatsApp!

💚 Join Our WhatsApp ChannelFormula for Heat Loss and Insulation Thickness

H = h x A x (Th – Ta)

Where:

- H = Heat loss (W)

- h = Heat transfer coefficient (W/m²·K)

- A = Surface area (m²)

- Th = Hot surface temperature (°C)

- Ta = Ambient temperature (°C)

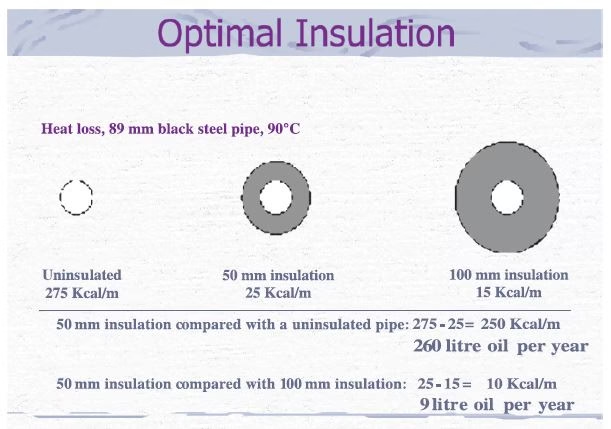

We’ll use the principle that heat moves from hot to cold, and insulation slows this down. We’ll examine how much heat is lost (or gained) with no insulation, a medium thickness, and a thicker layer.

Case 1: The Steaming Boiler – Quantifying Heat Savings (Hot Pipes)

- Pipe Temperature (Th): 150°C

- Ambient Temperature (Ta): 30°C

- Pipe Surface Area (A): 1 m² (for easy calculation per square meter)

- h for bare steel pipe: Let’s assume hbare = 15 W/m²·K (typical for convection/radiation).

Step 1: The “Naked” Pipe (No Insulation)

- Formula Applied (Convective Heat Loss):

H=hbare×A×ΔT - Calculation:

H=15×1×120=1800 Watts - Result: A bare pipe loses 1,800 Watts of heat per square meter. This is pure energy waste.

Step 2: Adding a “Light Coat” (50 mm Rockwool Insulation)

Now, we add insulation. The heat has to travel through the insulation.

- Identify Th: The insulation makes the outer surface temperature (Ts) of the insulation much cooler than the pipe. For 50mm Rockwool on a 150°C pipe, a realistic outer surface temperature

Tswould be around 40°C and Ta as 30°C - Formula Applied:

H=h×A×(Ts−Ta) - Calculation: H50mm=15×1× (40-30) =150 Watts

- Result: Heat loss drops to 150 Watts per square meter.

- Reduction%:

(1800−150)/1800×100%= 91.7%reduction.

Step 3: Adding a “Thick Coat” (100 mm Rockwool Insulation)

- Identify Th: With even thicker insulation, the outer surface temperature

Tswill be even closer to ambient. For 100mm Rockwool,Tsmight be around 35°C - Formula Applied:

H=h×A×(Ts−Ta) - Calculation: H100mm=15×1× (35-30) =75 Watts

- Result: Heat loss drops to 24 Watts per square meter.

- Reduction:

(1800−75)/1800×100%=95.8%reduction from bare pipe. - Comparison (50mm vs 100mm): 150-75

= 75Wfurther saved.

Summary for Hot Pipes (per m²):

- Without Insulation: 1,800 W loss

- With 50 mm Rockwool (Ts ≈ 40°C): 150 W loss 🔻 91.7% reduction

- With 100 mm Rockwool (Ts ≈ 35°C): 75 W loss🔻 95.8% reduction

Annual ROI Snapshot

- Bare pipe = 1.8 kW loss → ~15,800 kWh/year (~₹1.1 lakh/year at ₹7/kWh)

- 50 mm insulation saves ~14,000 kWh/year → pays back in <12 months.

Case 2: The Chilled Water Pipes – Quantifying Heat Gain (Cold Pipes)

- Pipe Fluid Temperature: (Th): 5°C

- Ambient Temperature (Ta): 30°C

- Temperature Difference (ΔT):

30°C−5°C=25°C(Heat flows from ambient to pipe) - Pipe Surface Area (A): 1 m²

- h for bare steel pipe: hbare = 15 W/m²·K

Step 1: The “Naked” Pipe (No Insulation)

- Formula Applied (Convective Heat Gain):

H=hbare×A×ΔT - Calculation: Hbare=15×1× (30-5) =375 Watts

- Result: A bare pipe gains 375 Watts of unwanted heat per square meter. This forces the chiller to work harder.

Step 2: Adding a “Light Coat” (25 mm Armaflex Insulation)

- Identify Th: The insulation helps keep the outer surface temperature (Ts) of the insulation warmer, closer to ambient. For 25mm Armaflex on a 5°C pipe, a realistic outer surface temperature

Tswould be around 20°C. - Formula:

H=h×A×(Ta−Ts) - Calculation:

H25mm=15×1×(30-20) =150 Watts - Result: Heat gain drops to 150 Watts per square meter.

- Reduction:

(375−150)/375×100%=60%reduction.

Step 3: Adding a “Thick Coat” (50 mm Armaflex Insulation)

- Identify Th: With thicker insulation, the outer surface temperature

TsTswill be even closer to ambient (and further from the dew point, preventing condensation). For 50mm Armaflex,Tsmight be around 25°C. - Formula:

H=h×A×(Ta−Ts) - Calculation:

H50mm=15×1×(30-25)=75 Watts - Result: Heat gain drops further to 75 Watts per square meter.

- Reduction:

(375−75)/375×100%=80%reduction from bare pipe. - Comparison (25mm vs 50mm):

150 W−75 W=75 Wfurther saved.

Summary for Chilled water Pipes (per m²):

- Without Insulation: 375 W gain

- With 25 mm Armaflex (Ts ≈ 20°C): 150 W gain🔻 60% reduction

- With 50 mm Armaflex (Ts ≈ 25°C): 75 W gain🔻 80% reduction

Annual ROI Snapshot

- Bare pipe adds ~3,300 kWh/year load on chiller (~₹23,000/year).

- 50 mm insulation saves ~2,600 kWh/year → payback in 6–10 months.

Beyond Energy: Hidden Costs of Poor Insulation

Energy waste is only half the story. Poor insulation also causes:

- Condensation & Corrosion Under Insulation (CUI) → higher maintenance costs

- Safety hazards from hot surfaces in boiler houses

- Productivity losses when cooling/heating systems underperform

- Shorter equipment life due to higher load cycles

Quick Reference: Insulation Match Guide

| Application | Recommended Insulation | Typical Thickness | Energy Savings Potential |

|---|---|---|---|

| Boiler pipes/tanks | Rockwool / Calcium Silicate | 75–100 mm | 20–30% fuel reduction |

| Chiller lines | Armaflex (elastomeric foam) | 25–50 mm | 10–20% cooling efficiency gain |

| Brine plant loops | Phenolic foam / PIR boards | 50–75 mm | 15–25% compressor savings |

| Cold water distribution | Polyiso / PIR | 25–40 mm | 10–15% HVAC energy cut |

Conclusion: From Losses to Measurable Savings

Insulation isn’t just about keeping heat in or cold out—it’s about turning invisible losses into measurable financial savings.

- Boilers: up to 92–96% heat loss reduction

- Chillers: up to 80% cooling loss reduction

- ROI: <12 months payback in most cases

- Bonus: lower maintenance, improved safety, longer equipment life

👉 In short, insulation is not an expense—it’s the smartest energy-saving investment a facility can make.

Do you agree? How has insulation helped your plant? 💬 Share your thoughts in the comments!

Very well Explained.

Such a detailed work on insulation is really admirable.

Yes Insulation saves lots of money through limiting energy losses