Introduction

Cleanrooms are the backbone of industries like pharmaceuticals, biotechnology, microelectronics, and healthcare. Their purpose is simple but critical: to protect products and processes from contamination. Among the many parameters that govern cleanroom performance, differential pressure (DP) is one of the most important — and one of the most misunderstood.

For decades, engineers and facility managers have believed that “more differential pressure is always better.” On the surface, it seems logical: if a higher pressure keeps contaminants out, why not crank it up? But in reality, excessive differential pressure can create more problems than it solves. In fact, this mindset is not just inefficient — it can be dangerous.

In this article, we’ll demystify cleanroom pressurization, explore why the “more is better” approach is flawed, and by maintaining optimal DP in cleanrooms (10–15 Pa), facilities we can achieve compliance, safety, and energy efficiency.

This article builds on our previous post about Air Changes per Hour (ACH) in cleanrooms — another commonly misunderstood metric. Read it here

The Role of Differential Pressure in Cleanrooms

Differential pressure is the difference in air pressure between two adjacent spaces. In cleanroom environments, it ensures that air always flows from cleaner to less-clean areas, preventing contaminants from migrating inward.

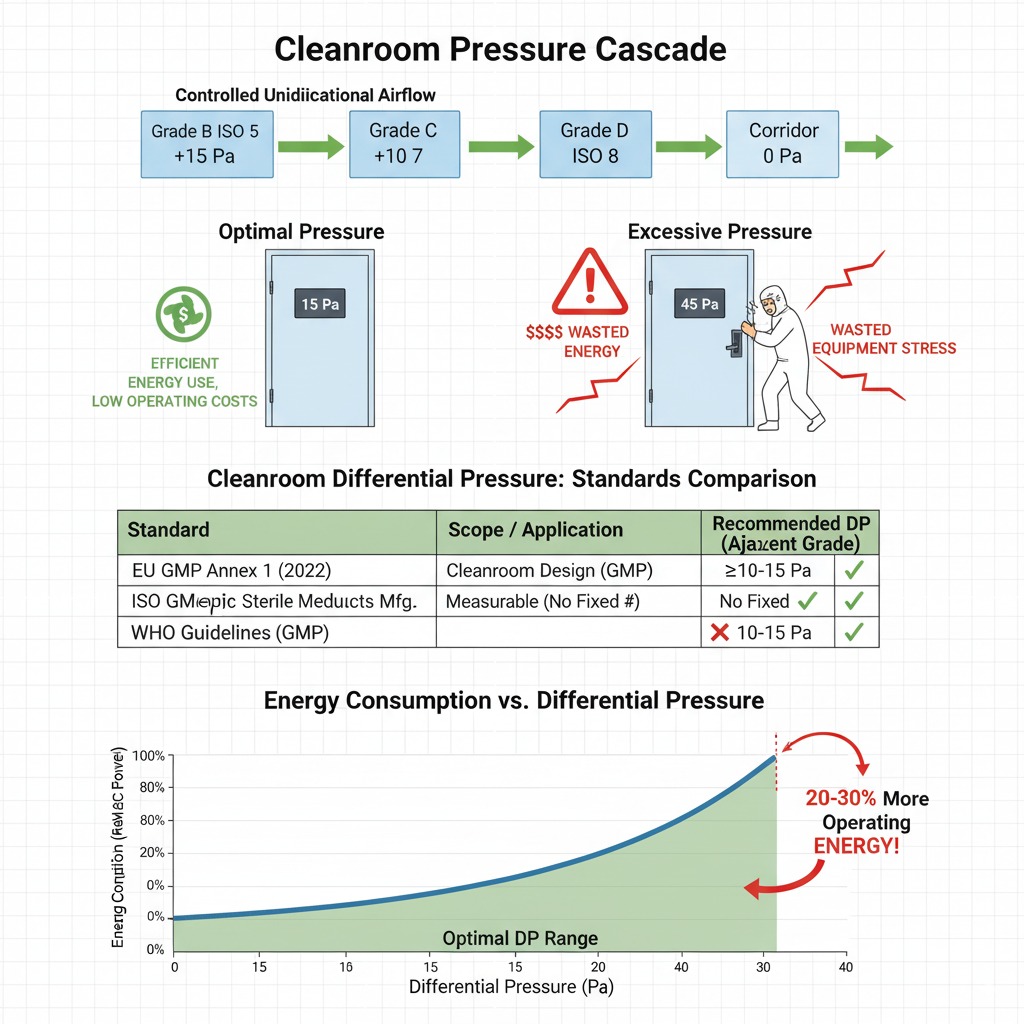

Typical pressure cascade design looks like this:

- Grade B / ISO 5 area (core cleanroom): Highest pressure

- Grade C / ISO 7: Slightly lower pressure

- Grade D / ISO 8 or unclassified corridor: Lowest pressure

The goal is to create a controlled, one-way flow of air — contaminants are pushed out, never pulled in.

The Common Belief: Higher is Safer

The logic behind the “more is better” approach is straightforward:

- If 15 Pascals (Pa) works, then 30 Pa must work even better.

- If the doors leak, higher pressure will keep contaminants out.

- If regulators require a minimum, exceeding it shows extra safety.

But while this thinking may come from good intentions, it ignores the science of airflow and the realities of cleanroom operation.

“This mindset often comes from auditors, managers, or even contractors who believe that going above the minimum standard is a sign of ‘extra safety.’ In reality, this isn’t safety — it’s waste.”

Problems Caused by Excessive Cleanroom Differential Pressure

1. Door Slamming and Safety Hazards

Excessive DP creates strong forces on doors. Operators may struggle to open or close them, leading to slamming that damages seals and creates particle bursts. In emergency situations, this becomes a serious safety risk.

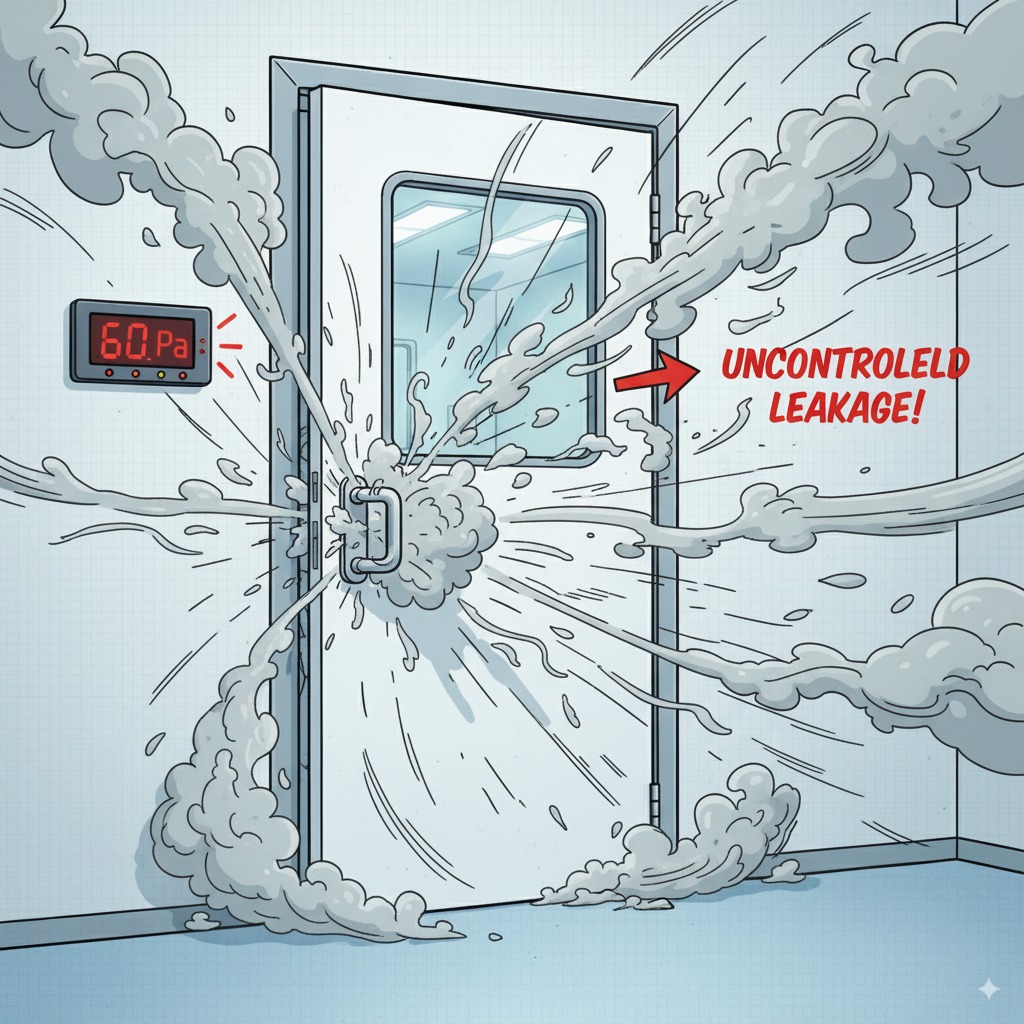

2. Uncontrolled Leakage

Cleanrooms are not hermetically sealed. Gaps around doors, pass boxes, and utility penetrations act as leakage points. Too much DP forces air through these cracks, potentially disturbing airflow patterns and dragging contaminants along unintended paths.

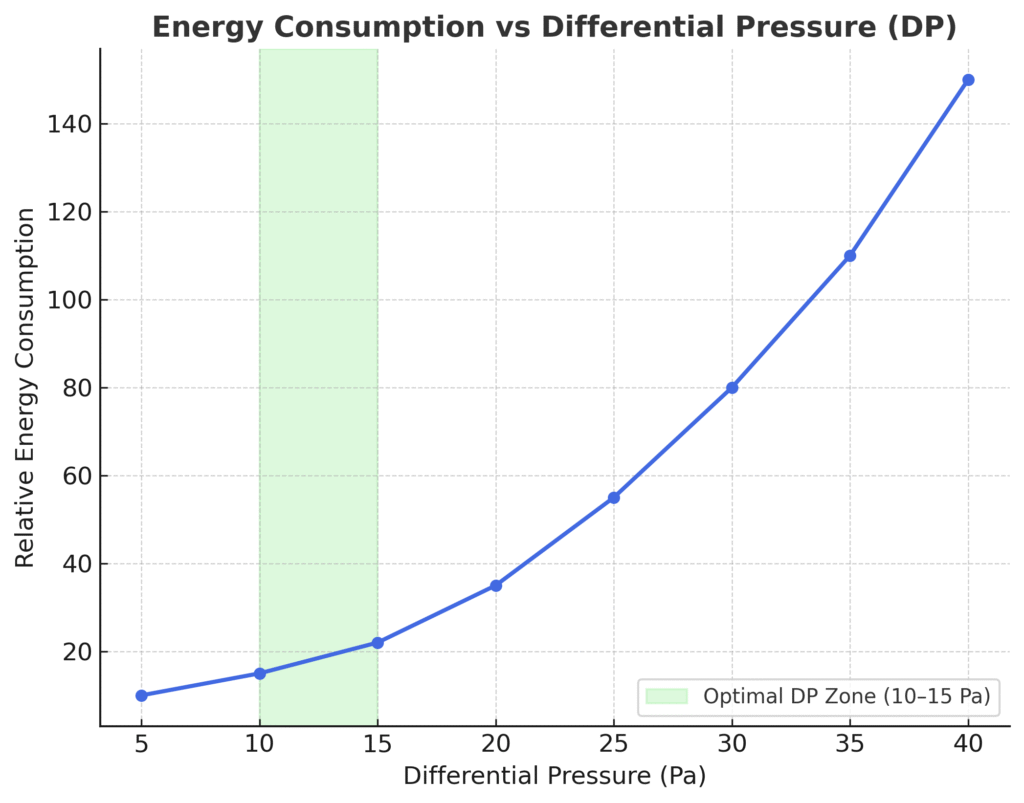

3. Energy Waste

Higher DP means more airflow is required. Fans must work harder, consuming significantly more energy. Studies show that over-pressurized cleanrooms may waste 20–30% more HVAC energy without adding any contamination control benefit.

A facility increasing DP from 15 Pa to 35 Pa can see fan energy rise by over 40% — with zero added contamination control benefit.

⚡ Enjoying this article? Stay updated with weekly HVAC & Energy Hacks — straight on WhatsApp!

💚 Join Our WhatsApp Channel4. Compromised Comfort and Usability

Personnel experience discomfort when pressure differences become extreme. A cleanroom that’s difficult to enter or exit disrupts workflow and increases operational risk.

What the Standards Actually Say

Contrary to popular belief, international cleanroom standards do not require excessive differential pressure. Instead, they specify minimum values to ensure contamination control.

| Standard | Recommended DP | Notes |

|---|---|---|

| EU GMP Annex 1 | ≥ 10–15 Pa | Between different grades |

| ISO 14644-4 | Not fixed, but measurable | Focus on maintaining cascade |

| WHO Guidelines | 10–15 Pa | For most pharmaceutical setups |

- EU GMP Annex 1 (2022): Recommends a pressure differential of ≥10–15 Pa between clean areas of different grades. (See official EU GMP Annex 1 PDF)

- ISO 14644-4: Does not fix a number but emphasizes maintaining a measurable pressure cascade. (Reference: ISO 14644-4 Standard Overview)

- WHO Guidelines: Suggest 10–15 Pa as sufficient for most pharmaceutical cleanrooms.

In other words, the goal is enough pressure to maintain directionality, not as much as possible.

The Dangerous Myth in Action: Real-World Example

At one pharmaceutical facility, engineers set a Grade B to Grade C differential pressure at 40 Pa, believing this would give an extra layer of protection. The results were disastrous:

- Doors slammed violently, breaking seals and hinges.

- Operators complained of fatigue and safety hazards.

- The excessive leakage paths disrupted unidirectional airflow in critical areas.

- Utility bills spiked due to the extra fan power required.

Ironically, the higher DP made the cleanroom less compliant with GMP expectations. After an audit finding, the facility corrected its cascade to 15 Pa — solving both compliance and comfort issues.

| ❌ Don’t Do | ✅ Do Instead |

|---|---|

| Maintain DP to 40 Pa for ‘extra safety’ | Maintain 10–15 Pa cascade |

| Ignore fluctuations | Maintain stability within ±2 Pa |

| Rely only on numbers | Validate with smoke visualization |

The Right Approach to Differential Pressure

1. Design with the Cascade in Mind

Always maintain a logical step-down of 10–15 Pa between cleanroom grades. This ensures airflow moves predictably without stressing the envelope.

2. Focus on Stability, Not Extremes

A stable DP (with ±2 Pa tolerance) is more valuable than a high DP that fluctuates wildly.

3. Validate with Smoke Studies

Visual airflow tests confirm whether pressurization achieves the intended directionality. This is far more reliable than chasing high numbers.

4. Use Smart Monitoring

Differential pressure sensors with alarms help maintain compliance without overcompensating. Alarms should trigger when DP falls below the set limit, not when it fails to exceed it excessively.

5. Don’t Ignore Energy Efficiency

Right-sized DP reduces fan energy, minimizes leakage, and extends filter life. Over time, this translates into substantial cost savings.

Key Takeaways

- More is not better. Excessive DP harms safety, comfort, compliance, and energy efficiency.

- Standards recommend 10–15 Pa, not 30 or 40 Pa.

- Stable, controlled cascades matter more than chasing higher numbers.

- Validation, not over-pressurization, is the path to true contamination control.

Final Thoughts

In cleanroom engineering, success doesn’t come from brute force — it comes from balance, precision, and control. The smartest cleanrooms aren’t the ones with the highest pressures, but the ones with the most stable and efficient ones

Differential pressure is one of the most powerful tools in cleanroom design and operation — but only when applied correctly. The myth that “higher is better” has cost industries millions in wasted energy, broken equipment, and failed audits. By following evidence-based guidelines and resisting the urge to over-engineer, we can build cleanrooms that are safe, efficient, and compliant.

Remember: In cleanroom pressurization, balance is safety. Not excess.

Have you ever worked in a cleanroom where excessive DP caused problems? Share your experience in the comments — your story could help others avoid the same costly mistakes.

Well Explained

Good breakdown and clear all the doubts so well.